Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

If you’re in the market for high-quality wood panels for your furniture, you might want to consider melamine blockboard. This type of engineered wood panel is made up of a core made from solid wood blocks or strips arranged side by side and sandwiched between layers of veneer or plywood. The result is a strong and versatile material that is perfect for a wide range of applications.

Melamine faced blockboard is a popular choice for furniture manufacturers because of its many advantages. For one, it is durable and long-lasting, which means that it can withstand years of wear and tear. It is also resistant to scratches, stains, and fading, which makes it ideal for use in high-traffic areas. Additionally, melamine blockboard is available in a wide range of colors and finishes, which means that you can easily find the perfect match for your design needs.

If you are planning to use melamine blockboard for your next furniture project, it is important to understand the basics of this engineered wood product.

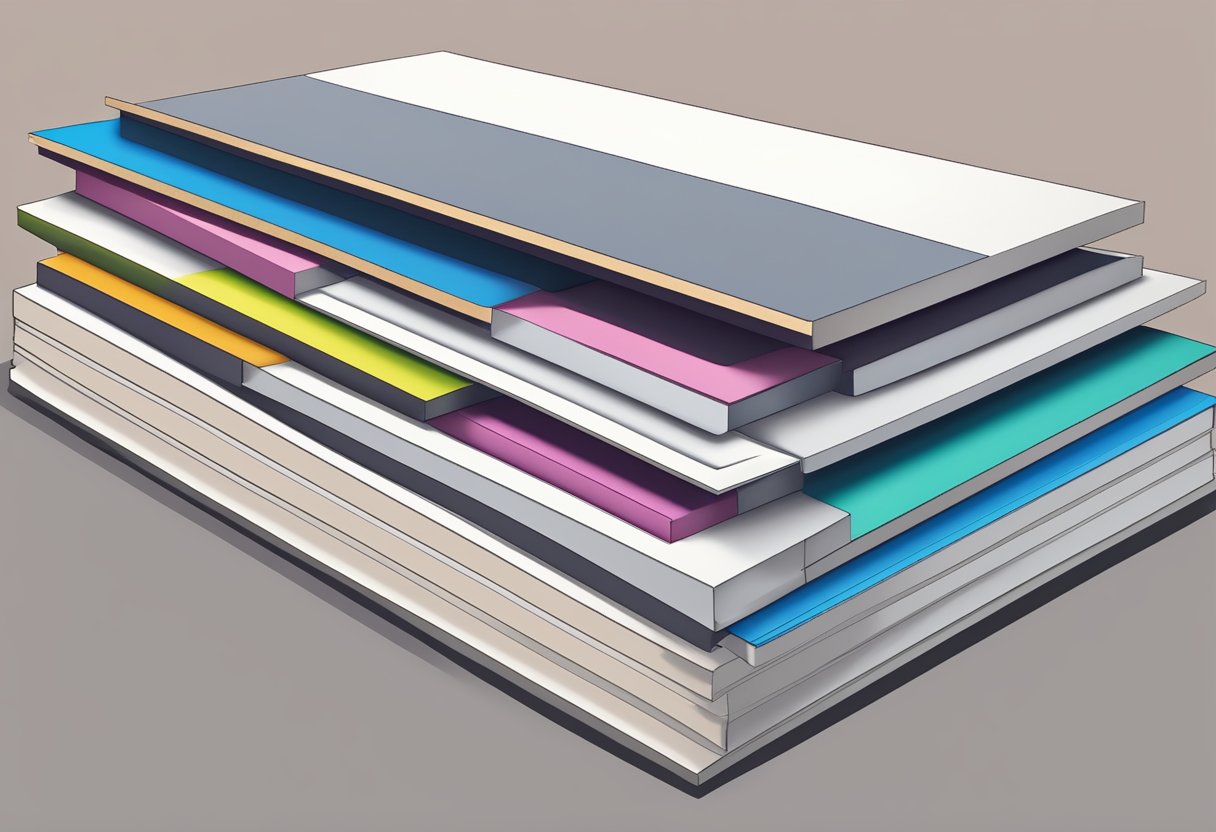

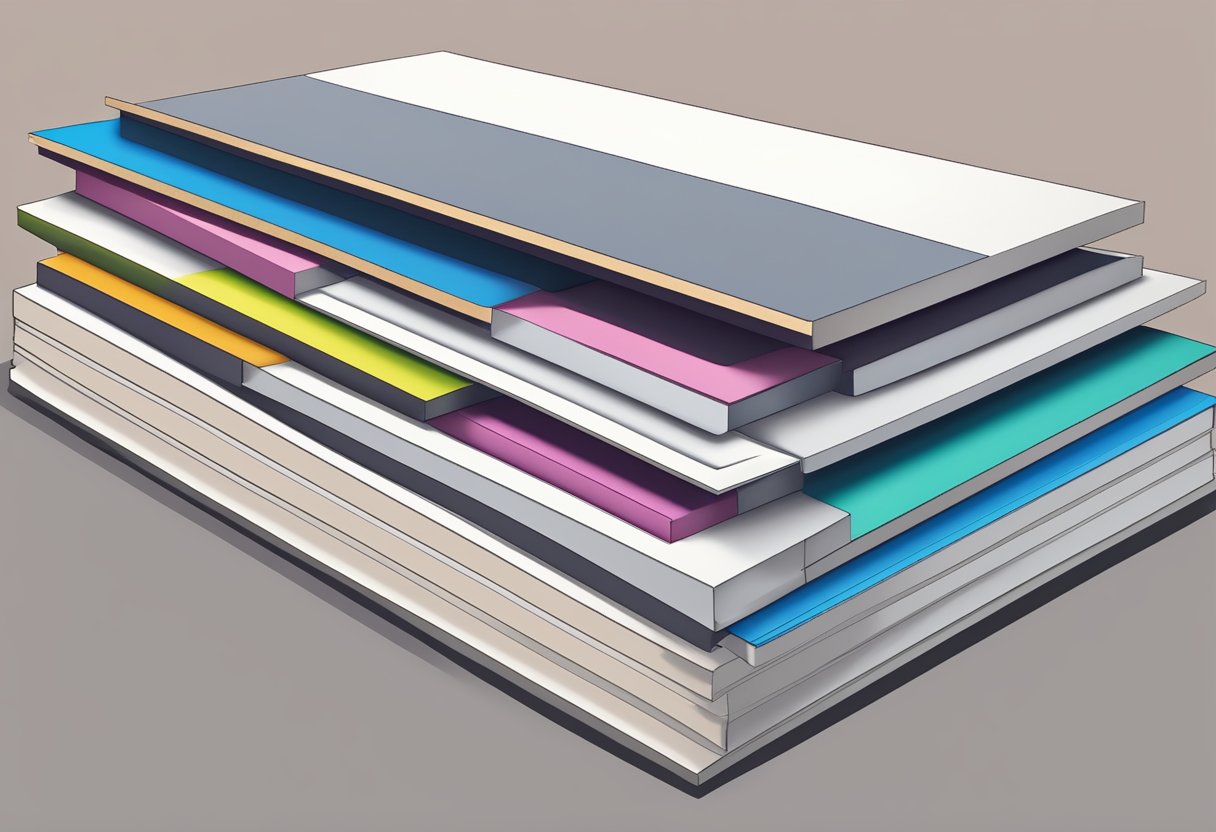

Melamine blockboard is made up of a core of softwood strips sandwiched between two layers of hardwood veneers. The veneers are coated with a layer of melamine resin, which gives the blockboard a smooth and durable finish.

The manufacturing process involves gluing the softwood strips together to form a solid block. The block is then sliced into thin sheets, which are glued to the hardwood veneers. The resulting product is a strong and stable board that is resistant to warping and cracking.

Melamine blockboard is available in a variety of types and grades to suit different applications. The most common types include plain blockboard, veneered blockboard, and melamine-faced blockboard.

Plain blockboard is the most basic type, with a plain surface that can be painted or laminated. Veneered blockboard, on the other hand, has a thin layer of hardwood veneer on the surface, which gives it a more attractive appearance. Melamine faced blockboard is coated with a layer of melamine resin on both sides, which provides a durable and easy-to-clean surface.

Melamine blockboard is also available in different grades, which indicate the quality and strength of the board. The most common grades include MR, BWR, and BWP. MR stands for moisture resistant, and is suitable for use in dry areas. BWR stands for boiling water resistant, and is suitable for use in areas with high humidity. BWP stands for boiling water proof, and is suitable for use in areas that are exposed to water.

Overall, melamine blockboard is a versatile and durable material that is ideal for use in a wide range of furniture applications.

Melamine blockboard is an engineered wood product that is made by sandwiching softwood strips between hardwood veneers that are covered with melamine paper. This type of blockboard is known for its durability, resistance to moisture, and thermal and acoustic insulation properties.

Melamine blockboard is highly durable and can withstand various stresses. The high-pressure process used to manufacture this type of blockboard ensures that the core is strong and can withstand heavy loads. It also makes the surface resistant to scratches, abrasions, and impacts.

Melamine blockboard is resistant to moisture and can withstand high humidity levels. The melamine paper covering the hardwood veneers protects the wood from water damage, making it ideal for use in areas with high moisture levels such as kitchens, bathrooms, and laundry rooms.

Melamine blockboard provides excellent thermal and acoustic insulation properties. The softwood strips used in the core of the blockboard provide good insulation against heat and cold, while the hardwood veneers and melamine paper covering reduce noise transmission. This makes melamine blockboard ideal for use in areas where sound insulation and temperature control are important, such as recording studios, theaters, and server rooms.

Overall, melamine blockboard is a versatile and durable material that offers excellent resistance to moisture, thermal and acoustic insulation properties. Its unique properties make it ideal for use in a wide range of applications, from furniture to interior design and construction.

Melamine blockboard is a versatile and durable material that can be used in a variety of applications. Here are some of the most common uses for melamine blockboard.

Melamine blockboard is a popular choice for furniture manufacturers because of its strength and durability. It can be used to make a variety of furniture pieces, including chairs, tables, cabinets, and bookshelves. The material is particularly well-suited for furniture that will be subjected to heavy use, such as office furniture or school desks.

One of the advantages of melamine blockboard is that it can be easily cut and shaped into a variety of sizes and shapes. This makes it an ideal material for custom furniture pieces. Additionally, the material is available in a wide range of colors and finishes, which makes it easy to match with existing decor.

Melamine blockboard is also a popular choice for interior decoration projects. It can be used to create wall panels, partitions, and decorative elements such as shelves and moldings. The material is particularly well-suited for high-traffic areas, such as hallways and entryways, because of its durability and resistance to scratches and dents.

One of the advantages of melamine blockboard for interior decoration is that it is available in a wide range of colors and finishes. This makes it easy to match with existing decor and create a cohesive look throughout a space. Additionally, the material is easy to clean and maintain, which makes it ideal for use in areas that are prone to dirt and dust.

Melamine blockboard is also used in a variety of construction projects. It can be used to create beams, columns, and other load-bearing elements where reliability is paramount. The material is particularly well-suited for use in humid environments, such as bathrooms and kitchens, because of its resistance to moisture.

One of the advantages of melamine blockboard for construction projects is that it is available in large sizes and can be easily cut and shaped to fit specific needs. Additionally, the material is lightweight, which makes it easy to transport and install. Finally, melamine blockboard is an environmentally friendly choice for construction projects, as it is made from renewable resources and can be recycled at the end of its life.

Melamine blockboard is a type of blockboard that is coated with melamine resin to enhance its durability and aesthetic appeal. Here are some of the advantages of using melamine blockboard:

Melamine blockboard is available in a wide range of colors and patterns, making it a popular choice for furniture and interior design. The melamine coating gives the blockboard a smooth and glossy finish, which enhances its visual appeal. Additionally, the coating is resistant to scratches, stains, and fading, which ensures that the blockboard retains its aesthetic appeal for a long time.

Melamine blockboard is easy to clean and maintain. The smooth and non-porous surface of the melamine coating prevents dirt, dust, and other particles from sticking to the surface. You can easily clean the blockboard with a damp cloth or sponge, and it will look as good as new. Additionally, the coating is resistant to moisture, which prevents the blockboard from warping or swelling when exposed to humidity or water.

Melamine blockboard is an affordable alternative to solid wood and other types of blockboard. It is made by sandwiching a core of solid wood blocks between two layers of melamine-coated veneer. This makes the blockboard lightweight, yet strong and durable. Additionally, the melamine coating reduces the need for additional finishing or painting, which saves time and money during the manufacturing process.

In summary, melamine blockboard is a versatile and cost-effective material that offers a range of benefits. Its aesthetic appeal, ease of maintenance, and cost-effectiveness make it a popular choice for furniture, interior design, and other applications.

When it comes to installing and handling melamine blockboard, there are a few key things to keep in mind to ensure a successful project. In this section, we’ll cover cutting and machining, as well as joining and finishing.

One of the benefits of melamine blockboard is that it can be easily cut and machined to fit your needs. However, it’s important to use the right tools and techniques to avoid damaging the material.

When cutting melamine blockboard, it’s best to use a saw blade with fine teeth to prevent chipping or cracking. You can also use a straightedge guide to ensure a straight cut. If you need to drill holes in the material, use a drill bit designed for use with melamine to prevent splintering.

Melamine blockboard can be joined using a variety of methods, including screws, nails, and dowels. When joining pieces together, it’s important to use the right type of fastener and to pre-drill holes to prevent splitting.

When it comes to finishing melamine blockboard, you have a few options. You can apply a coat of paint or varnish to the surface to give it a finished look, or you can use edge banding to cover the exposed edges of the material. Keep in mind that melamine blockboard is not suitable for staining, as it does not absorb the stain evenly.

In conclusion, with the right tools and techniques, installing and handling melamine blockboard can be a straightforward process. Keep these tips in mind as you plan your next project to ensure a successful outcome.

When it comes to selecting materials for your furniture, safety and environmental considerations are crucial. Melamine blockboard is a popular choice due to its durability, moisture resistance, and affordability. However, it is important to consider the potential risks associated with this material.

Melamine blockboard is made by bonding melamine resin to a blockboard core. While melamine is generally safe for everyday use, caution must be exercised during installation to prevent bending and warping. Additionally, the material’s weight requires careful handling. Formaldehyde is a known carcinogen and is present in both melamine and MDF. Formaldehyde emissions from melamine blockboard can cause eye, nose, and throat irritation, as well as respiratory problems.

To reduce the risk of exposure to formaldehyde, look for melamine blockboard that meets the E1 or CARB2 emission standards. These standards ensure that the formaldehyde emissions are within safe limits. You can also look for blockboard that has been treated with formaldehyde-free adhesive.

Melamine blockboard is not biodegradable and can be difficult to recycle due to the presence of melamine and formaldehyde. When disposing of melamine blockboard, it is important to follow your local regulations. In some areas, it may be considered hazardous waste and require special handling.

To reduce waste, consider repurposing or donating your melamine blockboard furniture. If you must dispose of it, try to find a recycling center that accepts melamine blockboard or contact a waste management company for guidance.

Overall, while melamine blockboard has many benefits, it is important to consider the potential risks associated with it. By selecting blockboard that meets emission standards and properly disposing of it, you can help ensure the safety of yourself and the environment.

If you are interested in the melamine blockboard market, you will be pleased to know that it is expected to grow significantly in the coming years. According to Market Strides, the global melamine board market will experience growth due to the increasing demand from the construction industry, as a result of population growth, urbanization, and infrastructure development.

The Melamine Board Market Report by DataIntelo also predicts a positive outlook for the market. The report states that the global melamine board market size is expected to grow at a CAGR of 5.5% from 2023 to 2032. This growth is attributed to the increasing demand for melamine boards in the furniture industry, as well as in the construction and interior decoration industries.

The Melamine Market by Share, Size, Trends, Growth Forecast report by Market Research Future projects a compound annual growth rate (CAGR) of 5.10% during the forecast period (2022 – 2030). The report also highlights the rising demand from major end-user industries such as building and construction.

Technavio’s Melamine Market Industry Analysis report predicts that the global melamine market size will grow by USD 434.96 million at a CAGR of 4.5% between 2022 and 2027. The report also notes that the increasing demand from the construction industry is driven by factors such as population growth, urbanization, and infrastructure development.

In conclusion, the future looks bright for the melamine blockboard market. With the increasing demand from the construction, furniture, and interior decoration industries, the market is expected to grow significantly in the coming years.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.