Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

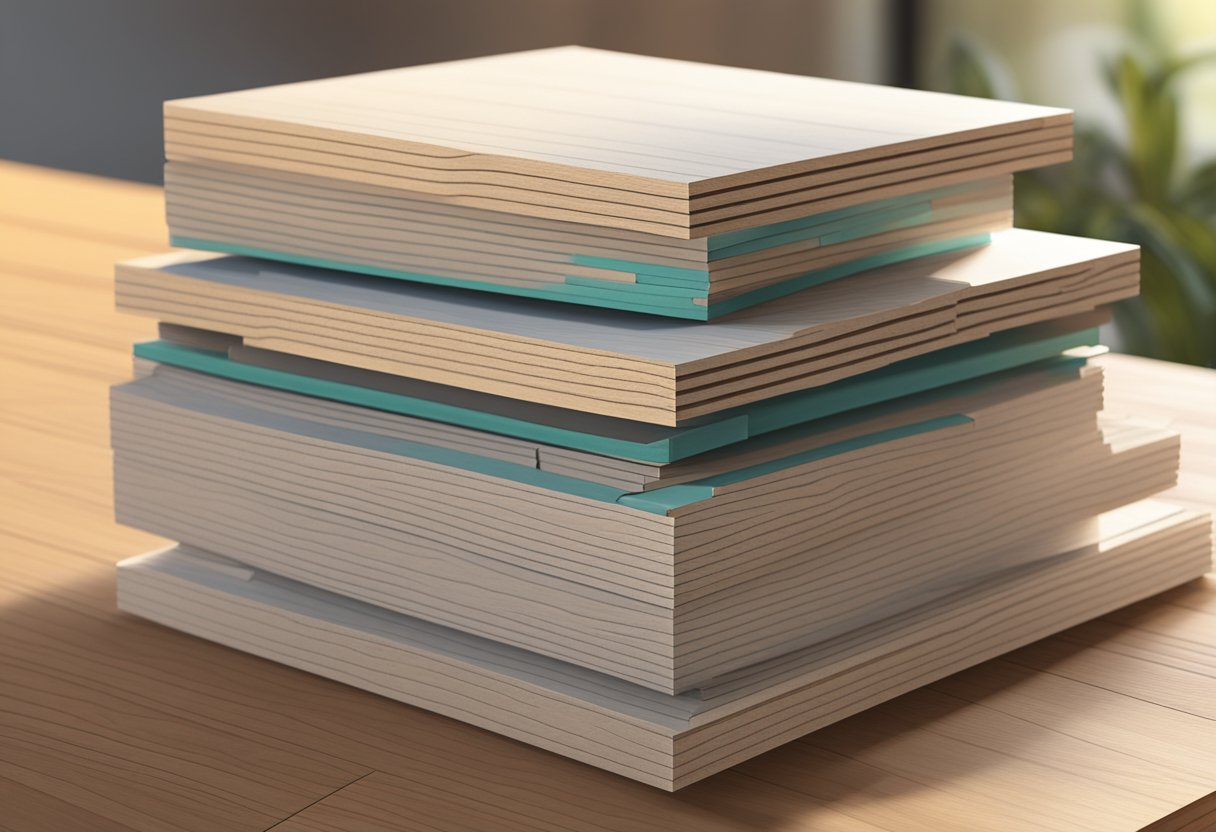

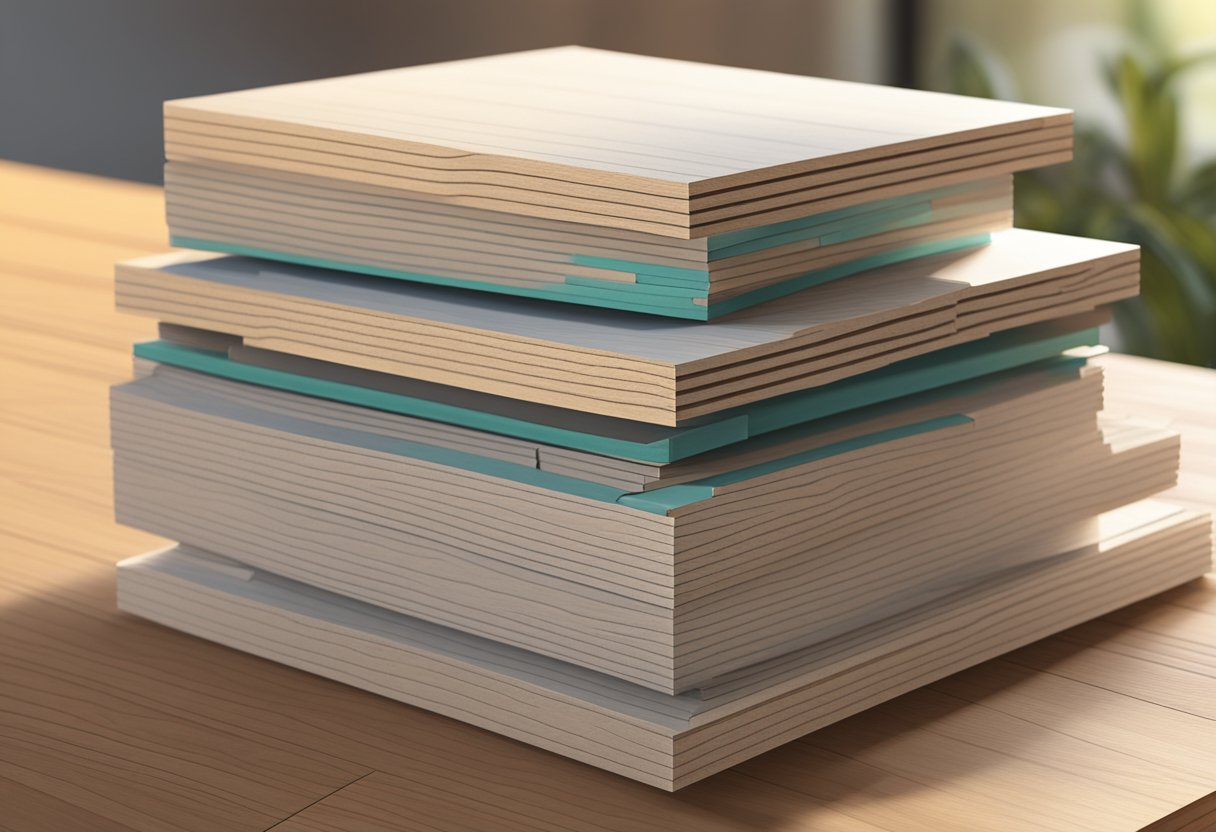

If you are in the market for building materials, you may have come across a melamine block board. Melamine block board is a type of engineered wood that is made up of a core of softwood strips or particles that are glued together and sandwiched between two layers of melamine-impregnated paper. The result is a strong, durable material that is resistant to scratches, moisture, and heat.

Melamine block board is a popular choice for a variety of applications, including furniture, cabinetry, and shelving. The melamine coating gives the board a smooth, uniform finish that can be customized to match any decor. Additionally, the melamine block board is easy to work with and can be cut, drilled, and routed using standard woodworking tools. With its many benefits, it’s no wonder that melamine block board is a favorite among builders and DIY enthusiasts alike.

Melamine block board is a popular type of engineered wood that is used in a variety of applications. It is made by bonding a melamine-impregnated paper to a particleboard or MDF (medium-density fiberboard) core. This process creates a smooth, hard, and durable surface that is resistant to scratches, stains, and moisture. In this section, we will discuss the properties of melamine block board in more detail.

Melamine block board is composed of a melamine-impregnated paper that is thermally fused to a particleboard or MDF core. The melamine paper is made by soaking decorative paper with melamine resin. The paper is then dried and pressed onto the core material using heat and pressure. The result is a smooth, hard, and decorative surface that is resistant to scratches, stains, and moisture.

Melamine block board is known for its durability and strength. The hard surface resists scratches, stains, and moisture, making it an ideal material for high traffic areas such as kitchens, bathrooms, and offices. The core material provides strength and stability, making it suitable for use in furniture, cabinetry, and other applications.

Melamine block board is highly resistant to moisture and heat. The melamine paper and core material are both engineered to resist moisture, making it an ideal material for use in humid environments. The hard surface is also highly resistant to heat, making it suitable for use in areas such as kitchens where high temperatures are common.

In summary, melamine block board is a popular type of engineered wood that is known for its durability, strength, and resistance to moisture and heat. It is a versatile material that is used in a variety of applications, including furniture, cabinetry, and flooring.

Melamine block board is an engineered wood product that is made by combining melamine resin and wood fibers. This process is done by using specialized machinery that is designed to produce high-quality boards that are both strong and durable.

The pressing technique used to manufacture melamine block board is an essential part of the process. The boards are pressed together using high-pressure machines that apply heat and pressure to the wood fibers and resin. This process ensures that the boards are strong and durable and can withstand a lot of wear and tear.

The adhesive used to manufacture melamine block board is another critical factor in the process. The adhesive must be strong enough to hold the wood fibers together but not so strong that it makes the boards brittle. The most common adhesive used in the manufacturing process is melamine formaldehyde resin.

Quality control is an essential part of the manufacturing process. To ensure that the boards are of high quality, they undergo rigorous testing before they are released into the market. The testing process includes checking the thickness, density, and strength of the boards. Boards that do not meet the required standards are rejected, and the manufacturing process is adjusted to correct the problem.

In conclusion, the manufacturing process of melamine block board is a complex and intricate process that requires specialized machinery and skilled workers. The use of high-quality materials, proper pressing techniques, and strict quality control measures ensure that the final product is of the highest quality.

Melamine block board is a versatile and durable material that has a wide range of applications in furniture construction, interior design, and commercial uses.

Melamine block board is a popular material for furniture construction due to its durability and resistance to scratches, moisture, and stains. It is commonly used for making cabinets, shelves, and tables. Additionally, it can be used for constructing bed frames, wardrobes, and other types of furniture.

Melamine block board is also used in interior design for creating a variety of decorative elements. It can be used to create wall panels, doors, and partitions. Moreover, it can be used for creating decorative shelves, bookcases, and other types of storage units.

Melamine block board is widely used in commercial settings due to its durability and ease of maintenance. It is commonly used for making office furniture, display counters, and whiteboards. Additionally, it can be used for creating flooring, wall cladding, and ceiling panels.

In conclusion, melamine block board is a versatile and durable material that has a wide range of applications in furniture construction, interior design, and commercial uses. Its smooth and non-porous surface makes it easy to maintain and ensures longevity.

Melamine block boards is an affordable option for those looking for a durable and long-lasting material for their furniture or home construction projects. Compared to solid wood, melamine block boards is much less expensive, making it a popular choice for those on a budget. Additionally, melamine block boards is lighter than solid wood, making it easier to transport and handle during construction.

Melamine block boards is a low-maintenance material that is easy to clean and maintain. It is scratch-resistant, watertight, and stain-resistant, making it a great option for areas that are prone to spills and messes. To clean melamine block boards, simply wipe it down with a damp cloth and mild detergent. Avoid using abrasive cleaners or sponges, as they can scratch the surface of the material.

One of the main disadvantages of melamine block boards is its environmental impact. The manufacturing process for melamine block boards involves the use of formaldehyde, which is a known carcinogen. While the amount of formaldehyde used in the production of melamine block boards has decreased in recent years, it is still a concern for those looking for environmentally-friendly materials. Additionally, melamine block boards is not biodegradable, meaning that it will not break down naturally over time.

Overall, melamine block boards is a cost-effective and low-maintenance material that is great for furniture and home construction projects. However, its environmental impact should be taken into consideration when choosing a material for your project.

When it comes to purchasing melamine block boards, there are a few things you should keep in mind to ensure you get a high-quality product that meets your needs. In this section, we will discuss some guidelines to help you make an informed decision.

One of the first things to consider when purchasing melamine block boards is its quality. High-quality boards are made with a solid core and have a smooth, even surface. Look for boards that have a uniform color and texture, without any visible defects or imperfections.

Melamine block boards come in a variety of sizes and thicknesses, so it’s important to choose the right one for your project. Consider the dimensions of the space you’re working with and the weight of the items you plan to place on the board. Thicker boards are generally stronger and more durable, but they may also be heavier and more difficult to work with.

When purchasing melamine block boards, it’s important to look for certifications and standards that ensure the board meets certain quality and safety requirements. Some common certifications to look for include the Environmental Protection Agency’s (EPA) TSCA Title VI and the California Air Resources Board (CARB) Phase 2. These certifications ensure that the board meets certain emissions standards and is safe for use in your home or office.

In summary, when purchasing melamine block boards, it’s important to identify high-quality boards, choose the right size and thickness for your project, and look for certifications and standards that ensure the board meets certain quality and safety requirements. By following these guidelines, you can ensure that you get a product that meets your needs and will last for years to come.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.