Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

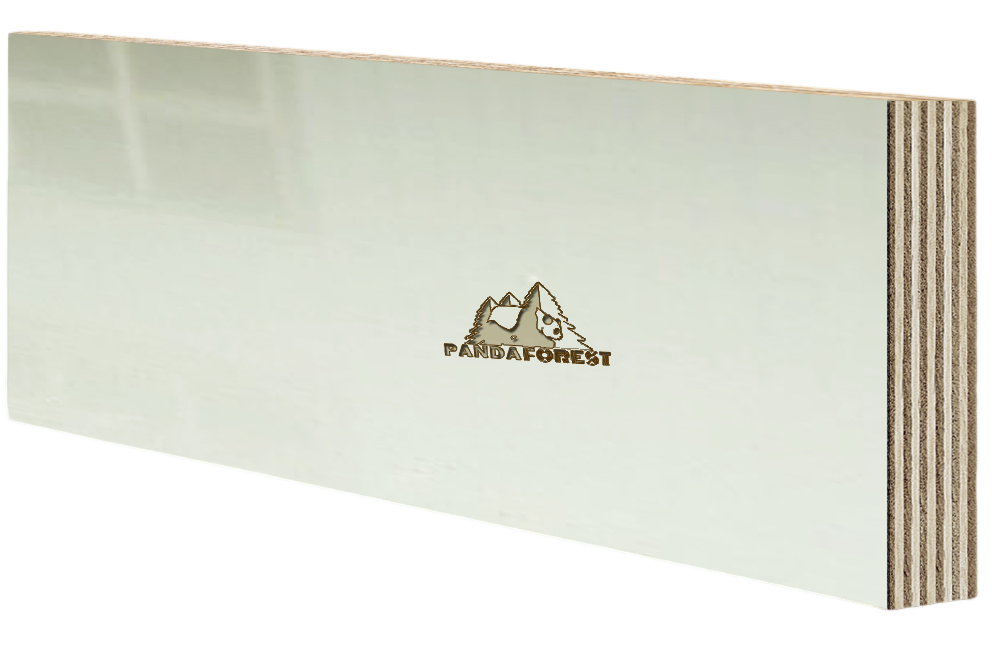

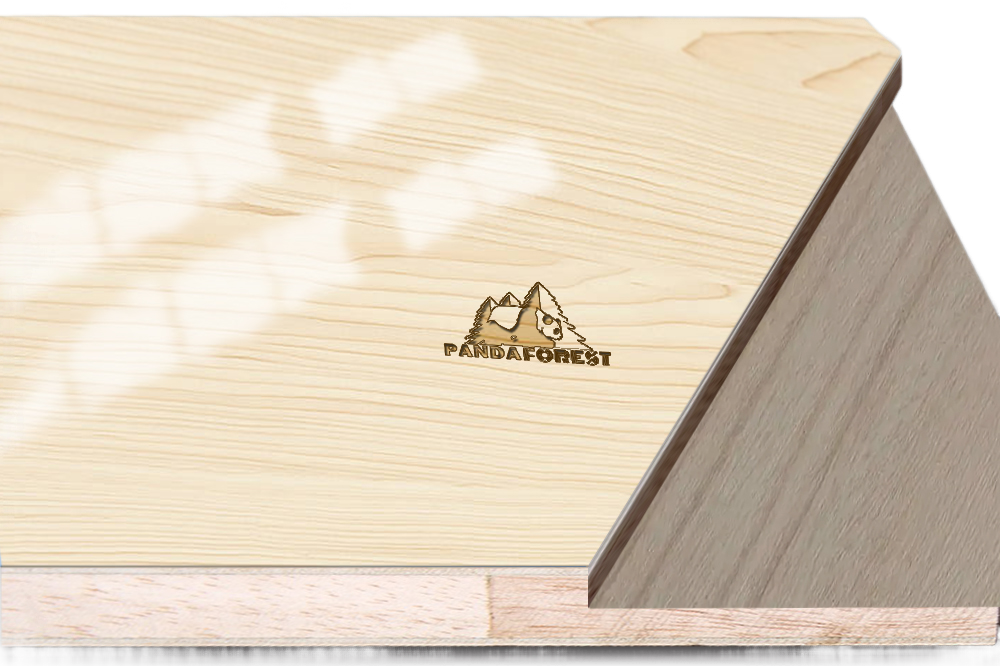

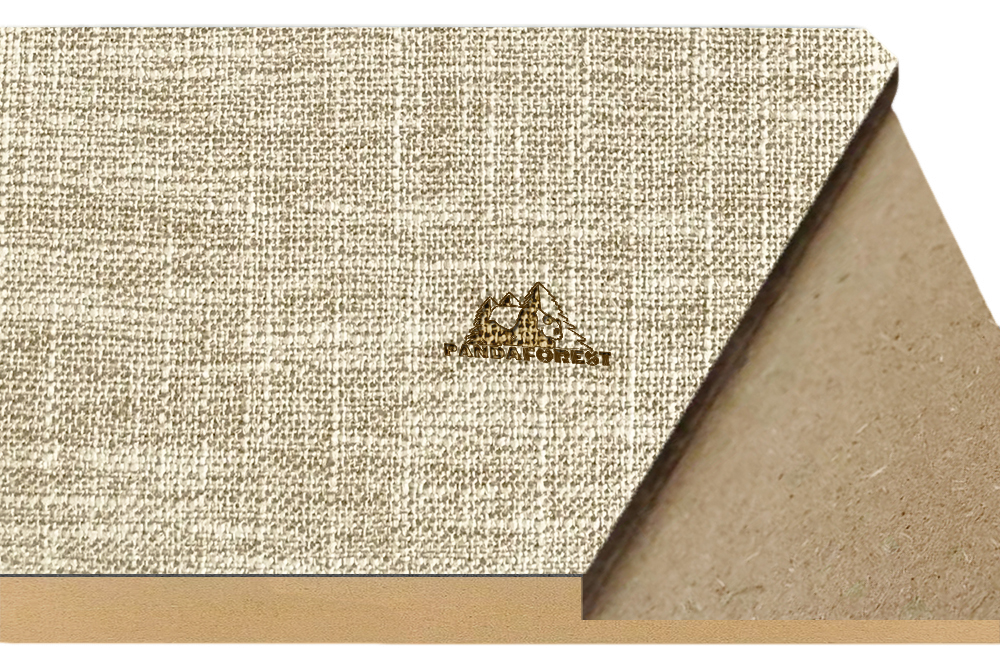

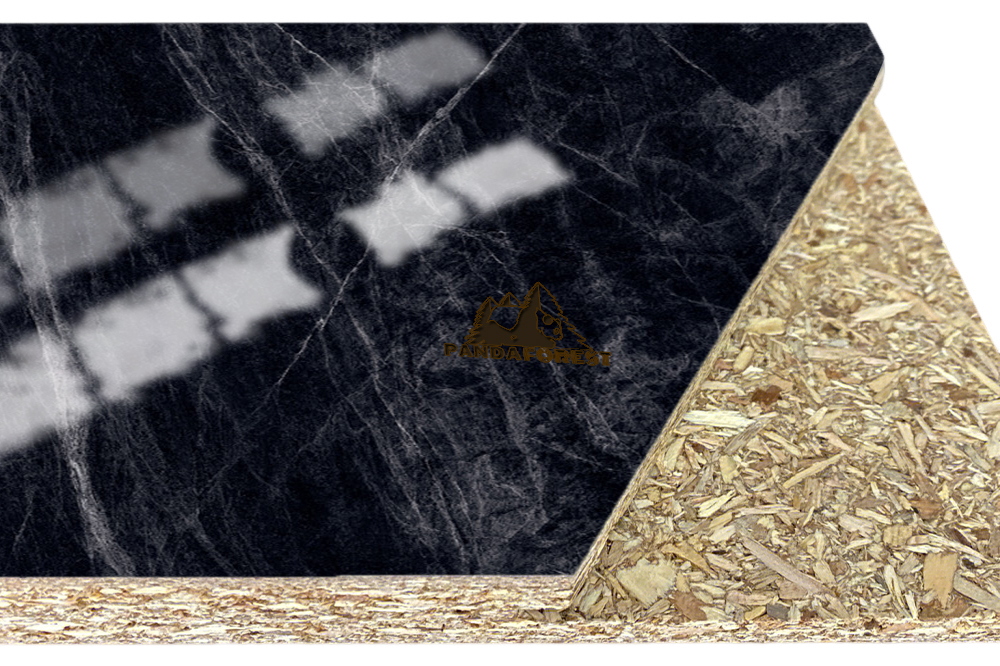

PANDAforest HPL Plywood Board ( High Pressure Laminates Plywood Board ) also known as a fire-resistant plywood board. It is a kind of engineered plywood overlaid on both sides with an stable, consistent, hard wearing HPL layers, can be effective flame retardant.

Get A QuotePreferred Plywood as the inner core material, the surface is covered with HPL layers, the structure is stable, the color is permanent and effective flame retardant.

HPL considered one of the most durable decorative surface materials and has special performance properties such as chemical, fire and abrasion resistance. Fireproof panels are widely used in interior decoration, furniture, kitchen cabinets, laboratory bench, exterior walls, architectural doors and other fields which are safer to use and have a longer service life.

We offer rich pure colours, also offer colors with simulated wood grain, Stone Gain or cloth textures. You just need to provide your ideas, and let us do the rest.

◎ Office & Residential furniture

◎ Bathroom stall dividers

◎ Toilet partitions

◎ Door skins

◎ Wall paneling

◎ Lab tabletops

◎ Cabinets or shelves

◎ Flooring in bathrooms or washrooms

◎ Decorative items

◎ Laminate flooring

◎ Outdoor enclosures.

Supports can be placed between beams at any point and can be used in any kind of formwork.

◎ Ceiling formworks

◎ Wall formworks

◎ Bridge formworks

◎ Tunnel formworks

◎ Special formworks

◎ Scaffolding

◎ Working platforms

| Grade | Size | Layer up | Weight (kg/sheet) | Core Materials |

Packing Unit (sheets) |

||||||

| AA | 1220x2440x3mm | /=/ | 5.2 | Hardwood Plywood | 200 | ||||||

| AA | 1220x2440x5mm | /=/ | 8.5 | Hardwood / Combi | 120 | ||||||

| AA | 1220x2440x6mm | /=/ | 10.5 | Hardwood / Combi | 100 | ||||||

| AA | 1220x2440x9mm | /=/ | 15.5 | Hardwood / Combi | 70 | ||||||

| AA | 1220x2440x12mm | /=/ | 20.5 | Hardwood / Combi | 50 | ||||||

| AA | 1220x2440x15mm | /=/ | 25.5 | Hardwood / Combi | 40 | ||||||

| AA | 1220x2440x18mm | /=/ | 31.0 | Hardwood / Combi | 35 | ||||||

| AA | 1220x2440x21mm | /=/ | 36.5 | Hardwood / Combi | 30 | ||||||

| AA | 1220x2440x25mm | /=/ | 43.0 | Hardwood / Combi | 25 |

| FORMALDEHYDE EMISSION:E0 ≤0.03 | |||||||||||

| Layer up:Cross-oriented | |||||||||||

| Moisture Content:8% – 15% (at time of despatch) | |||||||||||

| Dimensional Tolerances:±0.3mm | |||||||||||

| Straightness:±1.5mm | |||||||||||

| Density:650 kg/m³ (approximately) | |||||||||||

| Adhesive:E0 | |||||||||||

| Joint Group:For nails, bolts and screws | |||||||||||

| Finish:Unsanded faces, sanding / T&G | |||||||||||

| Branding:Each pallet of PANDAFOREST plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards | |||||||||||

| Storage:Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | |||||||||||

| Source:Plantation timber |

We can provide OEM orders according to your requirements and work with you to build your own plywood brand. Please contact our OEM Service Team.

China Forest Products Supply Co., Ltd.