Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

If you are in the construction industry, you know that the quality of materials used in your projects is crucial. One of the most important materials is formply, which is used for formwork in concrete construction. ROCPLY is a leading supplier and manufacturer of formply, offering a wide range of options to suit your specific needs.

ROCPLY offers formply with stress grades of F14, F17, and F22, each with its unique characteristics and benefits. F14 formply is designed for commercial construction sites and is known for its durability and adaptability. F17 formply, on the other hand, is a top-tier choice for formwork plywood, offering superior strength and cost savings. Finally, F22 formply is a cost-effective option with a high strength-to-weight ratio, making it a versatile choice for all applications.

No matter which stress grade you choose, ROCPLY’s formply is certified and guaranteed to meet your needs. With a commitment to quality and sustainability, ROCPLY is the ideal choice for your next construction project.

If you are looking for a reliable and high-quality construction material, Rocply Formply is an excellent choice. This plywood is specifically designed for formwork applications, and it offers superior strength, durability, and versatility. In this section, we will provide an overview of Rocply Formply, including its material properties and applications.

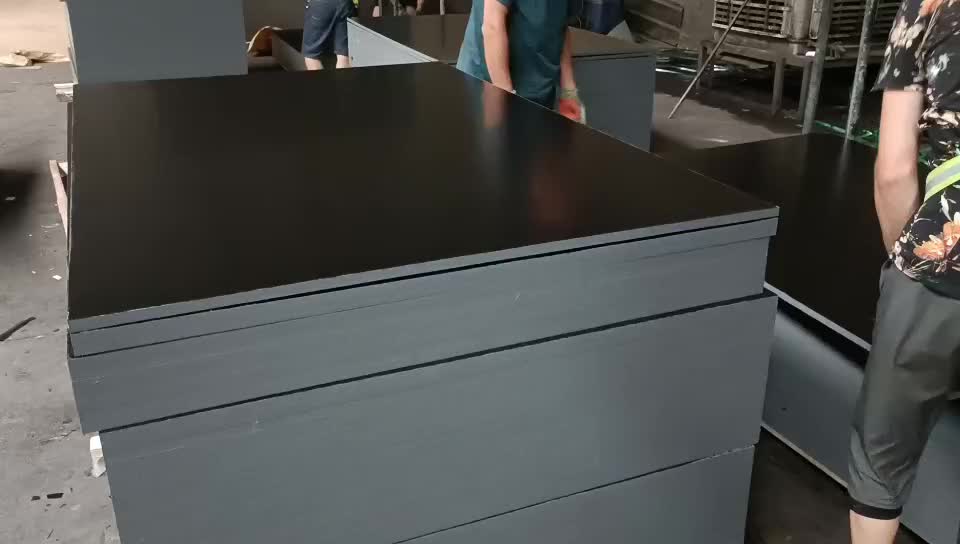

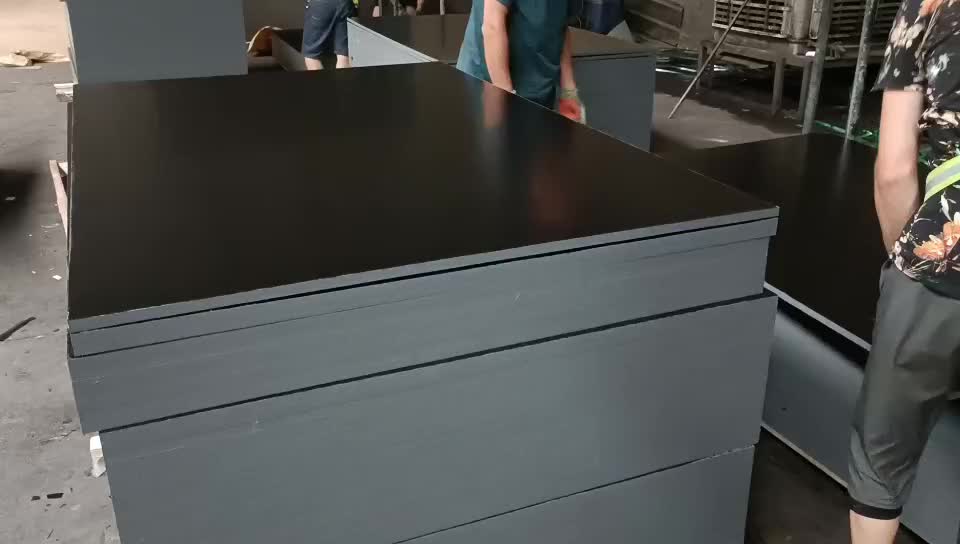

Rocply Formply is made from a combination of hardwood and birch veneers, which are bonded together with a high-density phenolic resin. This construction gives it excellent strength and durability, making it ideal for use in heavy-duty construction projects. It also has a smooth and consistent surface, which ensures a professional finish for your concrete structures.

One of the key features of Rocply Formply is its F17 stress grade. This rating indicates that the plywood has a high bending strength and stiffness, making it suitable for use in a wide range of formwork applications. It is also reusable, which means that you can save money on materials and reduce waste.

Rocply Formply is a versatile construction material that can be used in a variety of applications. It is ideal for use in concrete formwork, as it provides a smooth and consistent surface that ensures a professional finish. It can also be used in other construction applications, such as flooring, walls, and roofs.

One of the advantages of Rocply Formply is its ability to withstand harsh weather conditions. It is resistant to moisture, which makes it ideal for use in outdoor applications. It is also fire-resistant, which means that it can help to prevent the spread of flames in the event of a fire.

In conclusion, Rocply Formply is a reliable and high-quality construction material that offers superior strength, durability, and versatility. Its material properties and applications make it an excellent choice for a wide range of construction projects, and its ability to withstand harsh weather conditions and fire makes it a safe and reliable choice for your construction needs.

ROCPLY Formply is available in various sizes and thicknesses to meet your specific project requirements. The standard size of the family is 2400mm x 1200mm, but it can be custom cut to your desired dimensions. The thickness ranges from 12mm to 25mm, depending on the application and load requirements.

ROCPLY Formply is a premium-grade formply that is designed to withstand the rigors of heavy construction and mining operations. It is constructed from a mixture of hardwood and birch veneers with a high-density phenolic overlay. This unique composition gives it exceptional strength and durability, making it ideal for use in fixed formwork applications where strength and durability are non-negotiable.

ROCPLY Formply is certified to meet Australian Standard AS6669, which is the benchmark for quality and safety in the formply industry. This certification ensures that the product is of the highest quality and meets the stringent safety standards required for use in construction.

ROCPLY Formply has a high-quality off-form finish that is perfect for achieving a smooth and uniform surface on your concrete structures. The smooth surface finish is achieved by using a high-density phenolic overlay that is resistant to water, chemicals, and abrasion. This overlay also protects the formply from damage and prolongs its lifespan, ensuring that it can be used for multiple projects.

In conclusion, ROCPLY Formply is a versatile and durable product that is perfect for use in a wide range of construction applications. Its strength, durability, and surface finish make it an ideal choice for fixed formwork applications where quality and safety are of the utmost importance.

Before proceeding with the installation of ROCPLY formply, ensure that you have the following tools:

It is important to take necessary safety precautions while installing ROCPLY formply. Wear safety goggles and a dust mask to protect your eyes and lungs from dust and debris. Ensure that the work area is well-ventilated. Avoid using power tools near water or flammable materials. Keep children and pets away from the work area.

By following these installation guidelines, you can ensure that your ROCPLY formply is installed correctly and will provide long-lasting performance.

Maintaining the quality of your ROCPLY Formply F17 is crucial to ensure its longevity. Cleaning the formply is a simple process that can be done with a damp cloth. Avoid using harsh chemicals as they can damage the surface of the formply. If the formply is heavily soiled, use a mild detergent and a soft-bristled brush to gently scrub the surface. Rinse the formply thoroughly with clean water and wipe it dry with a clean cloth.

ROCPLY Formply F17 is designed to withstand harsh weather conditions and resist deformation, ensuring construction integrity. However, to extend its lifespan, it is important to follow these tips:

By following these simple maintenance and care tips, you can ensure that your ROCPLY Formply F17 remains in top condition and lasts for many years to come.

When it comes to purchasing ROCPLY Formply F17, there are two main factors to consider: price comparison and supplier selection.

ROCPLY Formply F17 is designed to offer a balance of quality and affordability, making it a versatile option suitable for different construction needs. However, it’s still important to compare prices from different suppliers to ensure you’re getting the best deal.

One way to do this is to create a table comparing the prices of different suppliers for the same quantity of ROCPLY Formply F17. This can help you quickly identify which supplier offers the most competitive pricing.

Another factor to consider is whether the supplier offers any discounts or promotions for bulk purchases. Some suppliers may offer lower prices for larger orders, so it’s worth asking about this before making your purchase.

When selecting a supplier for ROCPLY Formply F17, there are several factors to consider beyond just pricing. Here are a few things to keep in mind:

By considering both price and supplier selection factors, you can ensure that you’re getting the best value for your money when purchasing ROCPLY Formply F17.

Q: What is RocPly Formply? A: RocPly Formply is a type of plywood specifically designed for use in concrete formwork applications. It is manufactured to withstand the rigors of concrete pouring and shaping, providing a stable and durable surface for creating concrete structures.

Q: What sets RocPly Formply apart from regular plywood? A: RocPly Formply is engineered with special features to meet the demands of concrete formwork. It typically has a denser construction, higher quality veneers, and enhanced moisture resistance compared to standard plywood. These attributes help it maintain its structural integrity and smooth surface even under the pressure and moisture of concrete pouring.

Q: What are the advantages of using RocPly Formply? A: RocPly Formply offers several benefits, including:

Q: What sizes and thicknesses are available for RocPly Formply? A: RocPly Formply is typically available in standard sizes and thicknesses suitable for various formwork applications. Common thicknesses range from 12mm to 21mm, while standard sheet sizes include 1200mm x 2400mm and 1220mm x 2440mm. Custom sizes may also be available upon request.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.